Daily Inspiration: “Mastering the future? It’s more about awareness than it is about genius!”

August 30, 2022, BY JimCarroll"Mastering the future? It's more about awareness than it is about genius!" - Futurist Jim...

Daily Inspiration: “The future won’t wait for your panic to subside!”

June 14, 2022, BY JimCarroll"The future won't wait for your panic to subside!" - Futurist Jim CarrollHey, how about...

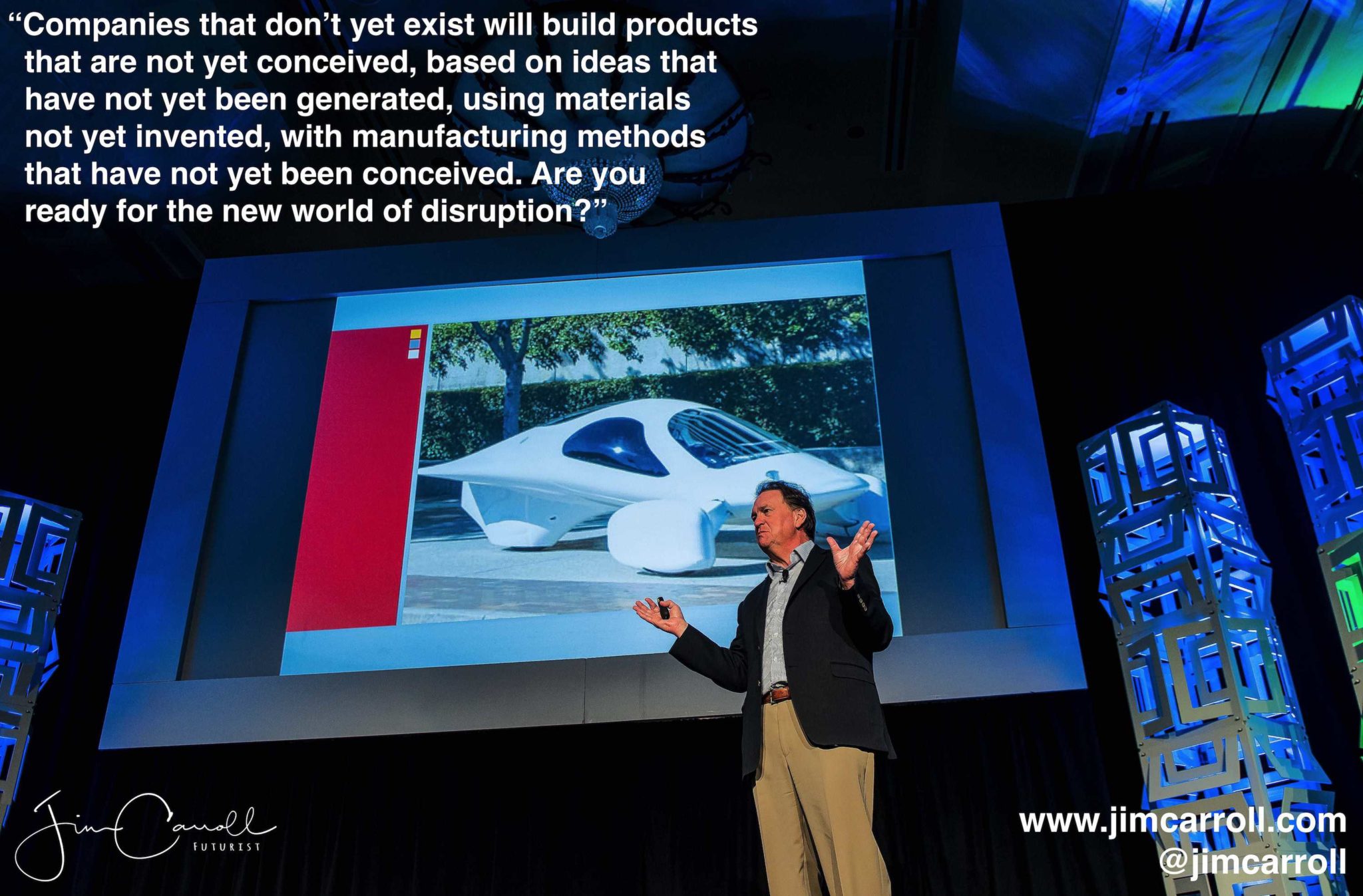

Trend Keynote: There’s More to Disruption Than You Think There Is!

October 27, 2017, BY JimCarrollDisruption is real, it's big, and it's happening faster than you think. My job as a futurist has...

Article: The Fabricator – “A look into the future of manufacturing”

October 18, 2017, BY JimCarrollAnother article on a recent keynote I did on the future of manufacturing; in this case, from The...

BBC Interviews me on #IoT : “The Brain Inside Our Homes” : It’s Early Days Yet in This Most Complex of Machines!

October 2, 2017, BY JimCarrollThe BBC gave me a call to chat about what is really going on with the Internet of Things...

Article: The Future of Manufacturing is in Acceleration!

September 18, 2017, BY JimCarrollCompanies that don't yet exist, will build products that are not yet conceived, based on ideas not...

Utilities, Disruption and ‘Connected Energy’: My Upcoming Keynote for SAP

August 28, 2017, BY JimCarrollWe're in the era of 'connected energy,' and everything is set to change in pretty dramatic...

The Story Behind the Picture: Is Your Brand from The Olden Days?

June 12, 2017, BY JimCarroll"A brand today can go from hero to zero in a matter of months...." In that context, you'd...

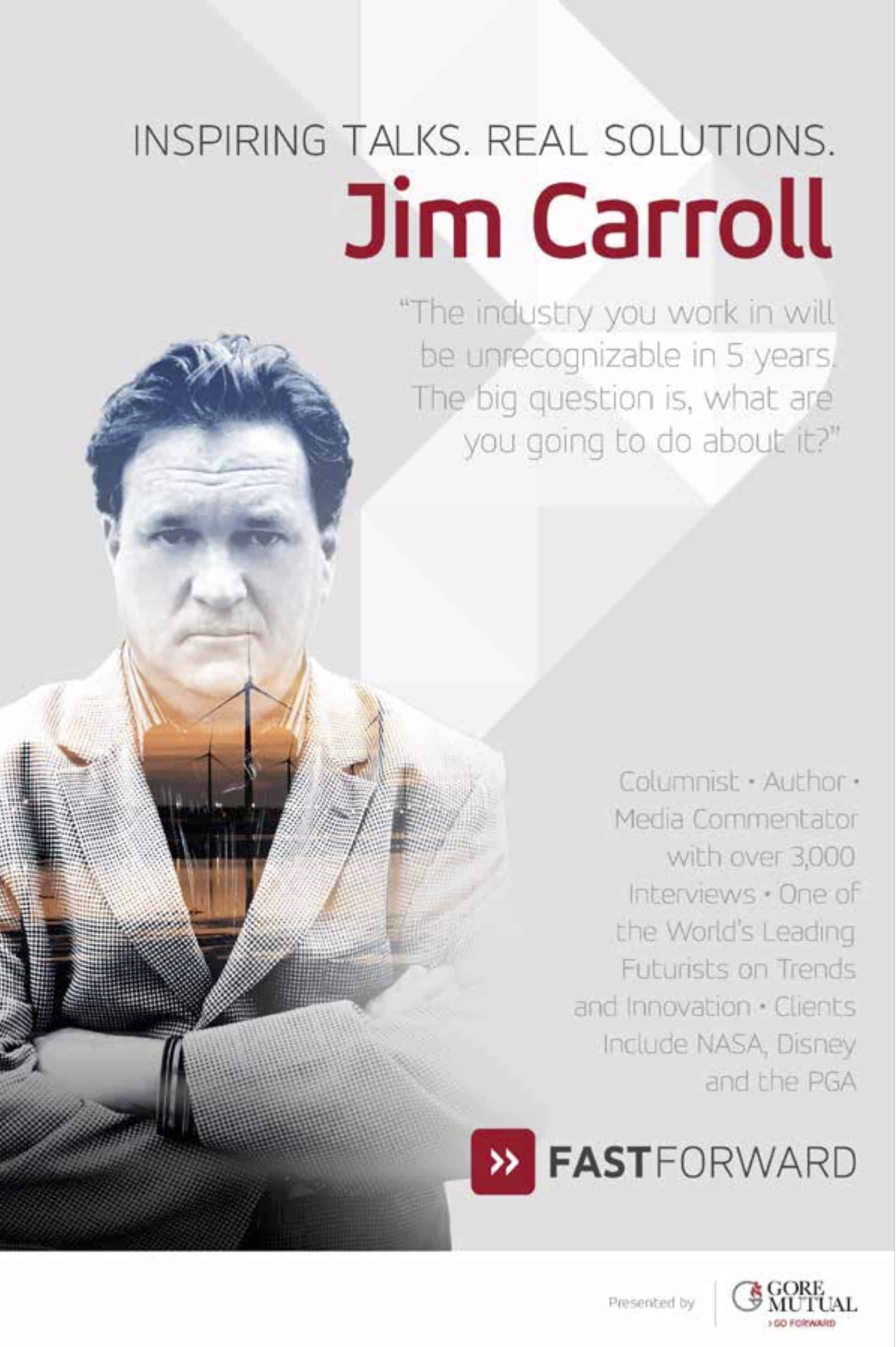

Fast Forward: Sharing the Stage with Chris Hadfield and David Suzuki

May 19, 2017, BY JimCarrollGore Mutual is a property and casualty insurance company located in Canada, and they are running a...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!