Golfing, 3D Printing, and the Future of Manufacturing: A Story of a Fellow Printing His Own Golf Wedges

July 28, 2017, BY JimCarrollOver the years, I've done many talks within the manufacturing industry, putting into perspective...

Keynote – Innovating in The Era of Accelerated Uncertainty: How to Adapt to the New World of Volatility

November 21, 2016, BY JimCarrollAnd we're off! A key client just confirmed that for the start of 2017, they need one of my key...

Trend: On The Future of Manufacturing

April 4, 2014, BY JimCarrollAt the end of the month, I'll be the opening keynote speaker for the Camstar Global Conference...

Article: The fast future is here: How innovators are driving emerging markets

January 15, 2014, BY JimCarrollLast autumn, I was the luncheon keynote speaker for the Electronics Representatives...

Article from PlasticsToday: “Find three ideas that you can implement to help get your company out of a rut”

September 30, 2013, BY JimCarrollPlastics Today, Chicago, September 9 —The competitor who could threaten your company's...

The future of manufacturing is happening now….

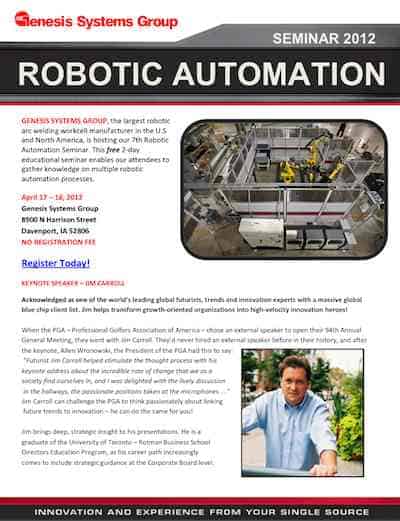

February 24, 2012, BY JimCarrollIn April, I'll be a dinner speaker for Genesis Systems Group annual Robotic Automation...

The future of North American manufacturing? Brighter than you think!

September 16, 2011, BY JimCarrollI've just returned from Las Vegas, where I was the keynote speaker for a new manufacturing...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!