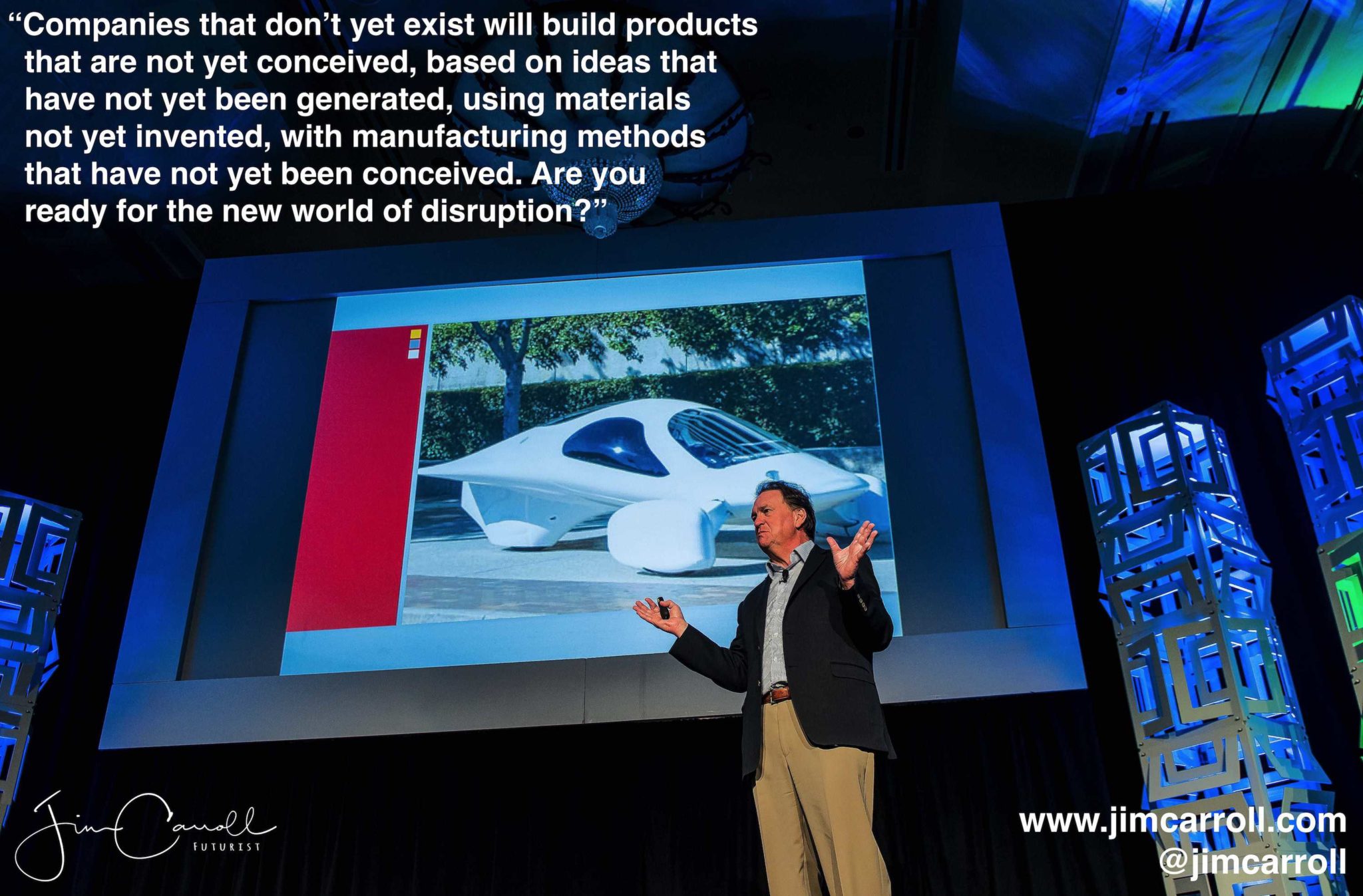

Article: The Future of Manufacturing is in Acceleration!

September 18, 2017, BY JimCarrollCompanies that don't yet exist, will build products that are not yet conceived, based on ideas not...

Keynote: Thing Big, Start Small, Scale Fast: Innovating in the Era of Disruption

June 16, 2017, BY JimCarrollI spent the morning yesterday with the Board of Directors of a multi-billion dollar credit...

Innovation, the Future, and Returning America to Optimism

October 21, 2016, BY JimCarrollWe live in interesting times, to say the least. It's a time in which some people see the...

Failing at the Future: Why Are Some Organizations Clogged with Organizational Sclerosis?

October 20, 2016, BY JimCarrollLet's talk about organizations that are clearly failures with the future -- those who are stuck in...

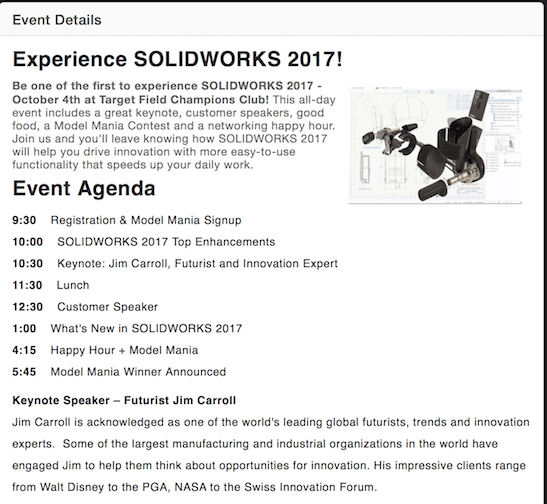

Keynotes: The Disruption and Reinvention of Manufacturing

October 3, 2016, BY JimCarrollWhile the popular media and opportunistic politicians portray a picture of a sector in crisis,...

Trend: Why Manufacturing Needs to Reinvent Itself – Fast!

November 10, 2015, BY JimCarrollI had a long conversation with a potential client in the manufacturing sector the other day;...

Video: “Made In The Cloud: Meet The Companies Leading The Manufacturing Sector’s Digital Revolution”

October 31, 2014, BY JimCarrollBack in September, Kennametal, a leading global manufacturing / machine parts company, invited me...

Trend: On The Future of Manufacturing

April 4, 2014, BY JimCarrollAt the end of the month, I'll be the opening keynote speaker for the Camstar Global Conference...

A “blast from the past from 2009 – “Canada announces end of economic relationship with US, & a bold new strategy to 2020”

November 21, 2012, BY JimCarrollSo I was on the phone today with the CEO of a major global organization headquartered in...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!