Daily Inspiration: “Mastering the future? It’s more about awareness than it is about genius!”

August 30, 2022, BY JimCarroll"Mastering the future? It's more about awareness than it is about genius!" - Futurist Jim...

Why Innovation Thrives in the Building of Sandcastles!

February 16, 2019, BY JimCarrollI'll be busy studying some key innovation issues for the next week. I have assembled a crack...

Article: Artificial Intelligence & Robotics In Construction: ‘Massively Transformative’

January 17, 2019, BY JimCarrollWhen I spoke in Oman last November, I spent a little bit of my time on stage talking about...

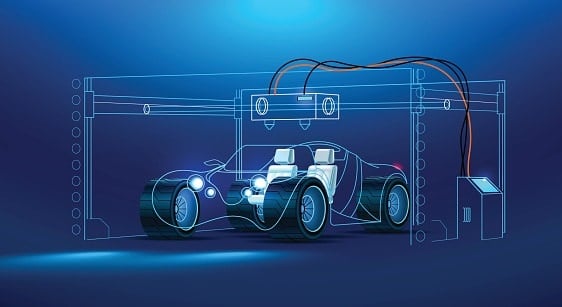

19 Trends for 2019: #11 Spatial Intelligence and Data In 3 Dimensions

January 16, 2019, BY JimCarrollWe're moving from a world of two-dimensional 'location intelligence' - think of all the things...

Article: The Fabricator – “A look into the future of manufacturing”

October 18, 2017, BY JimCarrollAnother article on a recent keynote I did on the future of manufacturing; in this case, from The...

Article: Futurist Says “Fast & Furious” Changes Coming to Manufacturing

October 6, 2017, BY JimCarrollThe folks at New Equipment Digest interviewed me a few weeks back for an article on...

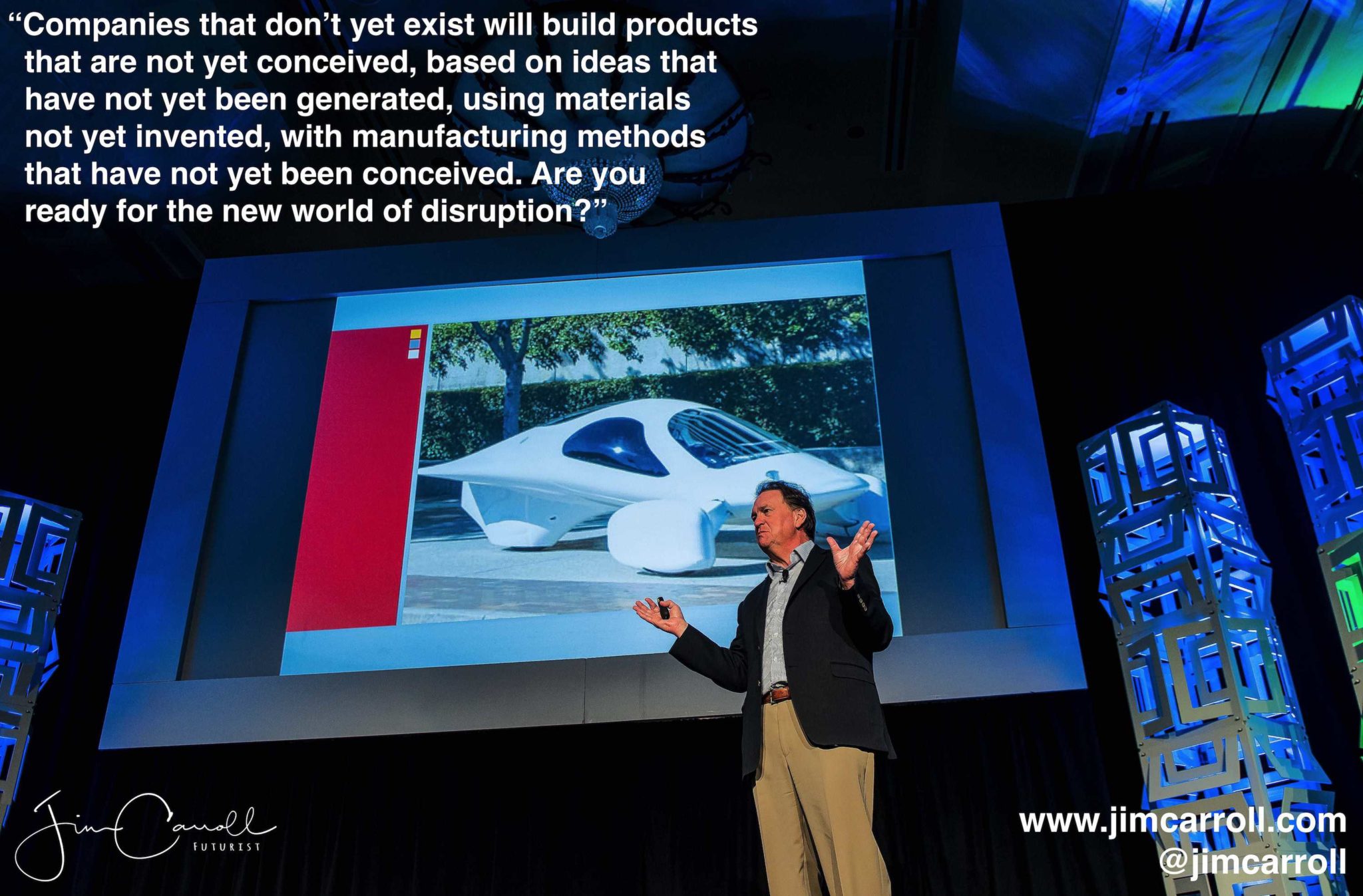

Article: The Future of Manufacturing is in Acceleration!

September 18, 2017, BY JimCarrollCompanies that don't yet exist, will build products that are not yet conceived, based on ideas not...

Utilities, Disruption and ‘Connected Energy’: My Upcoming Keynote for SAP

August 28, 2017, BY JimCarrollWe're in the era of 'connected energy,' and everything is set to change in pretty dramatic...

Upcoming Keynote: Future of Retail (in the era of Amazonian Disruption!)

June 26, 2017, BY JimCarrollThis fall, I'm headling a major retail event in Las Vegas - Xcelerate 2017! Details are...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!