Daily inspiration: “Insurmountable opportunities…..can be beat!”

April 4, 2019, BY JimCarroll“Those ‘insurmountable opportunities’ that block your way can always be...

“Womp Womp”, The Politics of Hate, and Why I Applaud my Partner Leading Authorities!

June 21, 2018, BY JimCarrollOver a 25 year time span, I have built a remarkably successful career as a speaker, speaking to...

Video: How I Work With You – Customization & Research

April 6, 2018, BY JimCarrollTake a look at my client list. I've developed a worldwide reputation for keynotes and talks at...

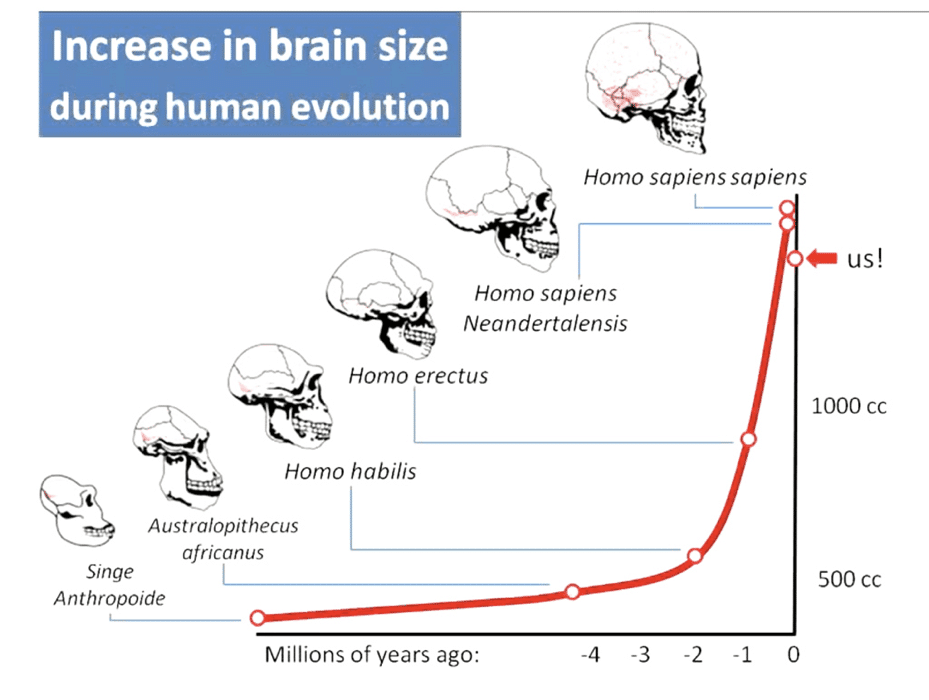

Video: Putting Your Mind Inside a Yottabit Ball

March 26, 2018, BY JimCarrollSo, I had a potential client ask, "do you have any really futuristic video clips that don't involve...

Want to Fire Up Your Event a Notch? Watch These Clips!

March 23, 2018, BY JimCarrollThe National Fire Protection Association has booked me to headline their annual conference in Las...

Video: The Future of Retail? It’s Fast!

March 9, 2018, BY JimCarrollDo you want to book the same old boring speaker who will show up and deliver a canned message -...

Daily Inspiration: Follow Me!

December 17, 2017, BY JimCarrollGet inspired, every day! I start my weekday morning with my coffee, my laptop, and a stage photo....

Article: The Future of Manufacturing is in Acceleration!

September 18, 2017, BY JimCarrollCompanies that don't yet exist, will build products that are not yet conceived, based on ideas not...

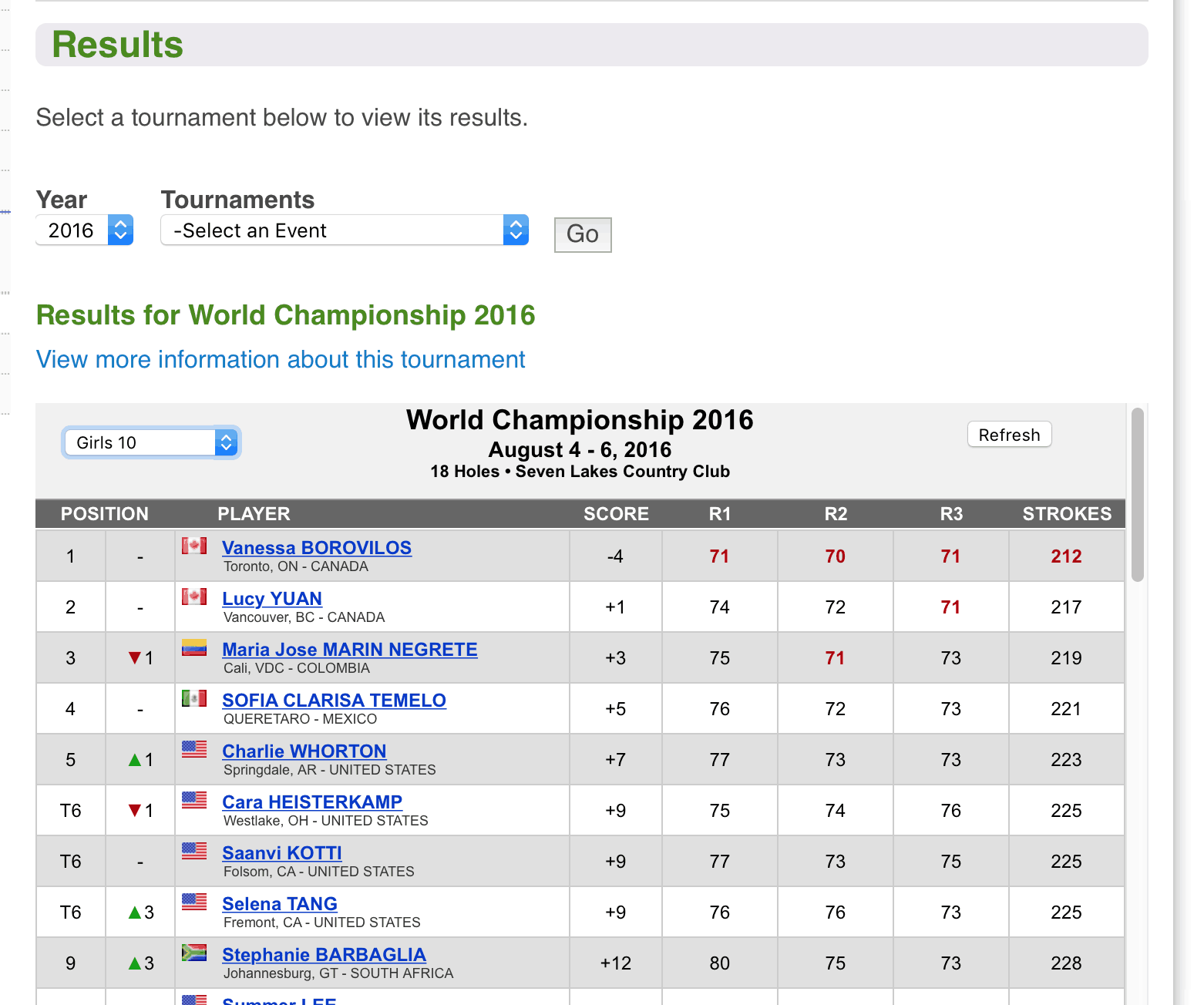

Growing the Game – A Shoutout to a Canadian Champion!

August 6, 2017, BY JimCarrollAnyone who tracks me know that I am passionate (if not slightly pathetic) golfer, and I've...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!